Context

When it comes to camming or tooling a job, routing is a mandatory process and it is a most important part. A job's complexity is not only determined by the number of layers and the complexity in design, but it also depends on the outing process. We have a specific customer whose routing design is always very much complicated even though the board looks very simple.

Solution

A clean outline layer is required to create an error free rout layer. Our concentration should be on fixing the problems with outline layer before we move in to the rout creation. Because when we start fixing the issues in outline layer, we have to fix it for hours if the supplied outline is not good.

Process

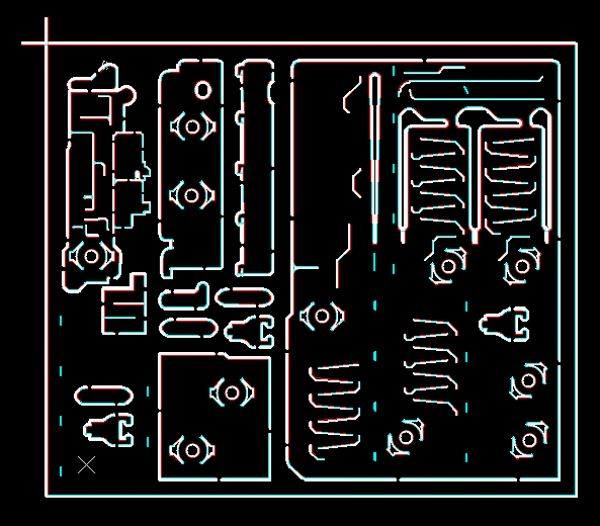

Recently we received such a design from this customer which had around fifty internal cut outs and the board shape been irregular. If we look at the board it will be hard to separate the board and cutouts as they were so close to each other and cutouts occupying most part of the board. Outline layer supplied with the data was very poor on this particular design as we noticed disconnection in outline at many locations and smaller radius which cannot be routed. So, this design not only required fixing but also a highest level of concentration to make sure all the necessary features are routed. Apart from this we had to take critical decision for choosing router bits which was done so correctly.

Results

This design took around 8 hours for processing and when we sent the completed to customer, we received an appreciation email from customer saying that end user was so happy with the routing done on this job. Also, we were informed that the decision made by our engineers was so good and the report we sent to them regarding routing was so useful. Now we are happy to say that we are a part of their business growth and also trustful outsourcing partner.