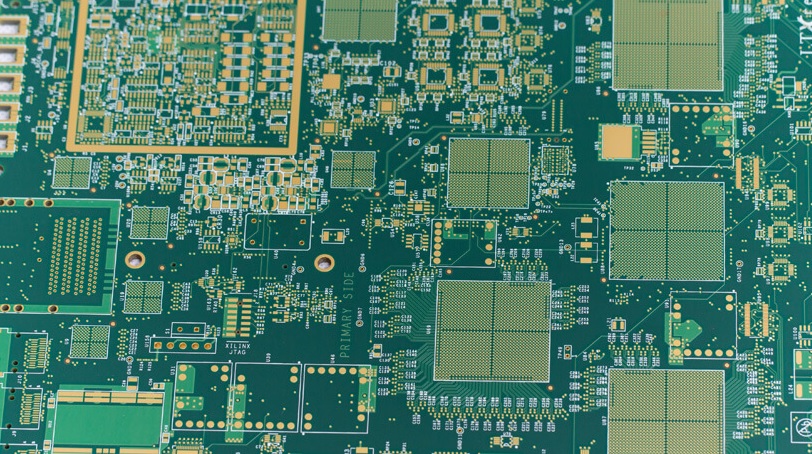

Context

The customer is in the PCB manufacturing industry for more than 25years and recently they upgraded their machines to handle high complex designs. Even though they had the machinery capabilities, they were short of engineering resources to meet the daily output. In this situation, one of our current customers recommended Parav Engineering as an reliable outsourcing partner, capable of handling complex technologies and having a proven record of jobs being handled with quality and on time delivery. As a result, the customer chose Parav Engineering as a dedicated outsourcing partner for all their CAM related process and almost like an in-house team.

Solution

Complex jobs will be given to the most experienced engineer in the team. Since we are involved in the PCB industry for more than 15 years, most of our engineers are well experienced in handling all types of complex jobs. So complex jobs are sent on time with good quality.

Process

Cammer who start working on the job with more complexity will process the data clean up, customer array and panelisation. Meanwhile EDIT process will be completely done by another cammer. Simultaneously quality check will be done for each process as soon it is completed. After completing the whole job, changes noticed during quality check will be re-verified and image comparison will be done. So quality will not be compromised in any situation. With this good internal system our customers are confidently sending jobs to us on a regular basis.

Results

With our wonderful team work, we have been regularly processing complex jobs and sending back on the same day which could have taken two working days to sent back. Now we became a trusted outsourcing partner for this customer and we are happy that we have become a part of their business growth.